Prof. Dr.-Ing. Andrea Iris Schäfer

Phone: +49 721 608-26909

andrea.iris.schaefer@kit-ct.de

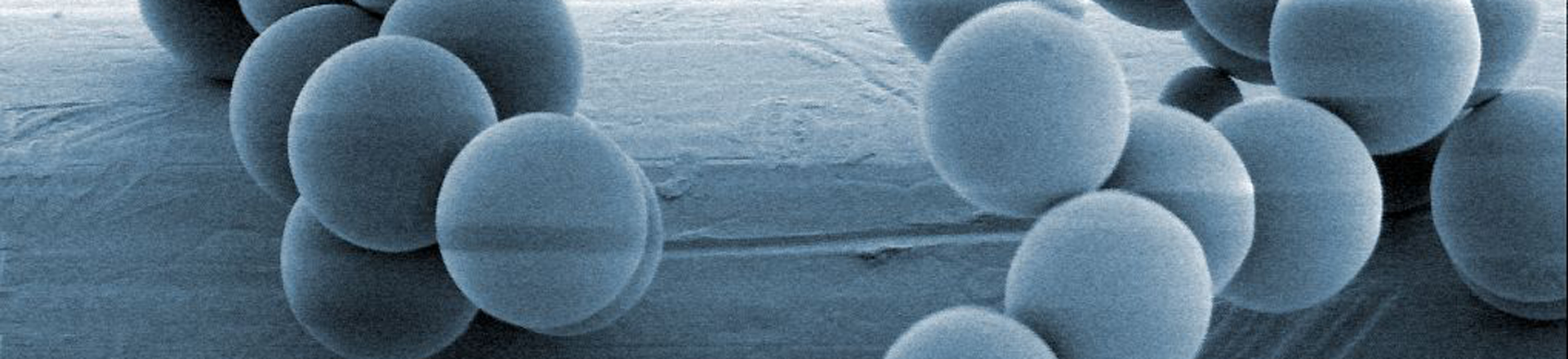

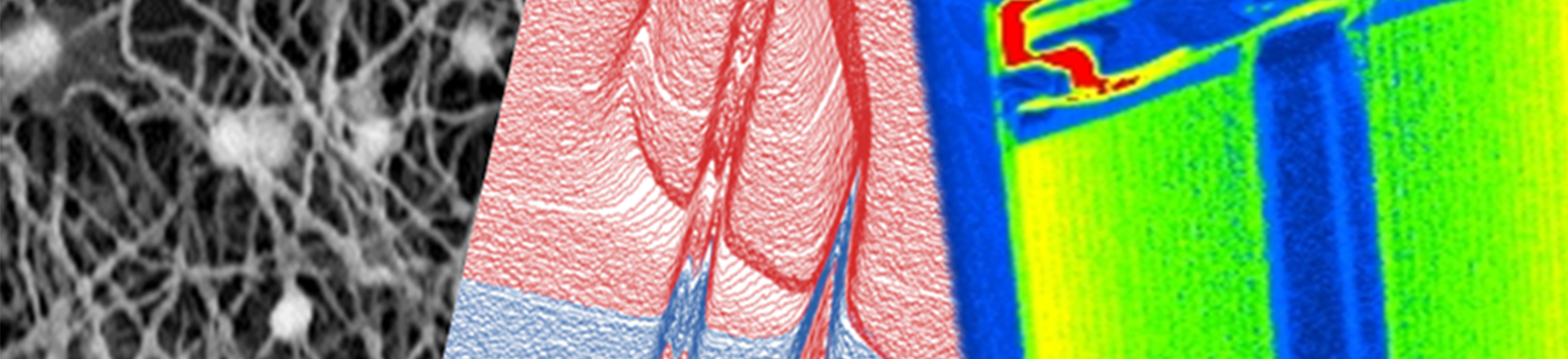

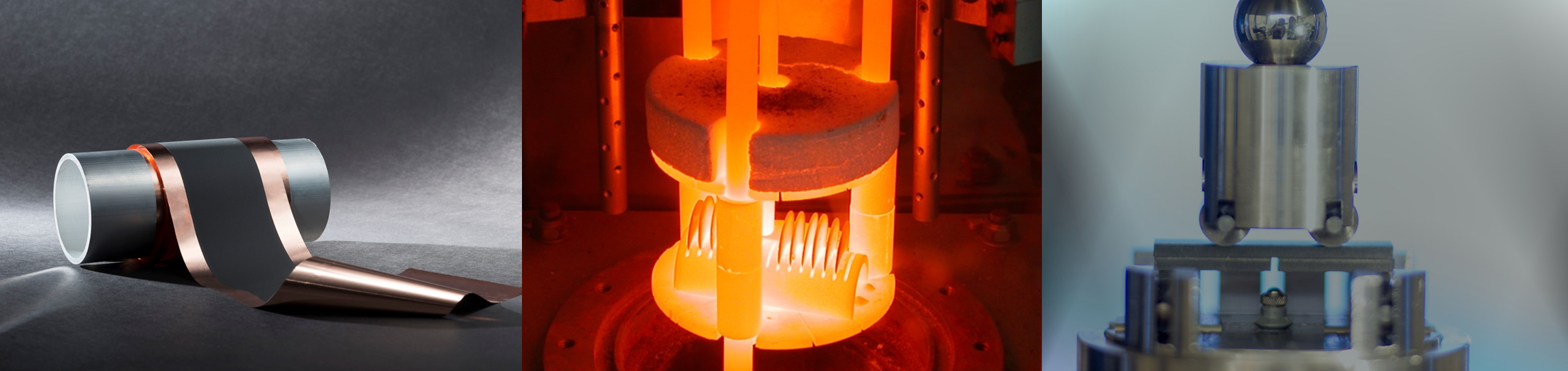

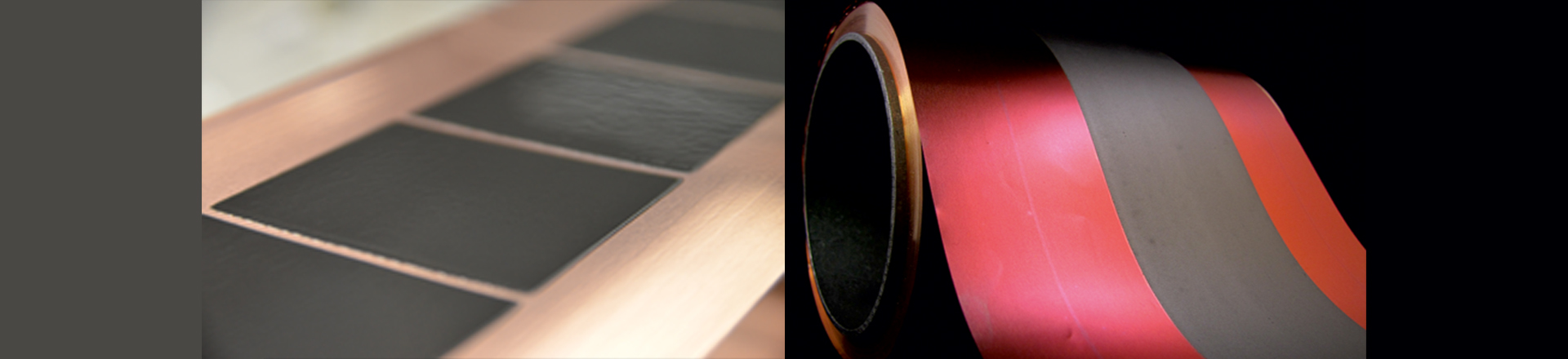

The TTU Membrane Materials & Processes offers its customers basic and application-oriented investigations on the subject of membranes for water treatment. This includes the design and development of new materials, their characterization, detection of fouling and the interpretation of procedures.

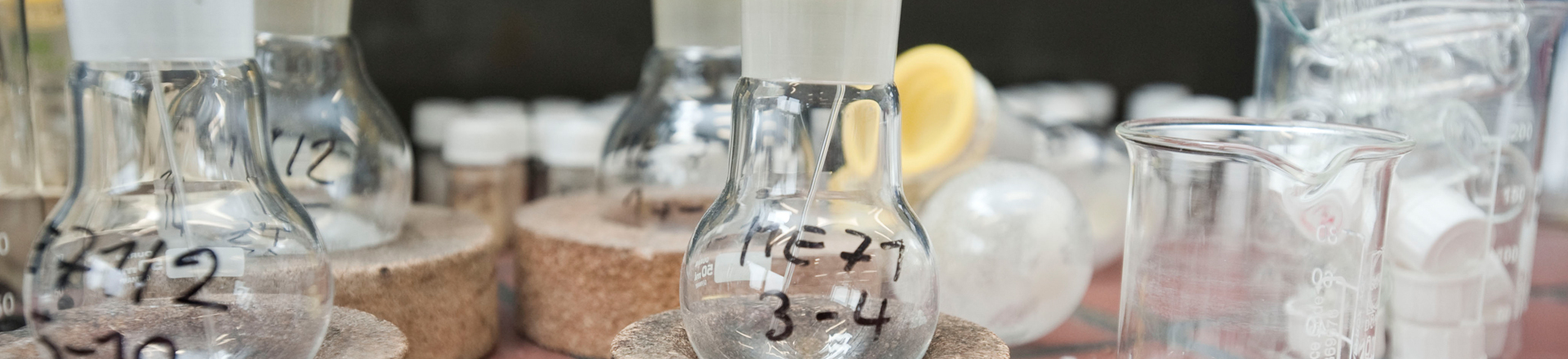

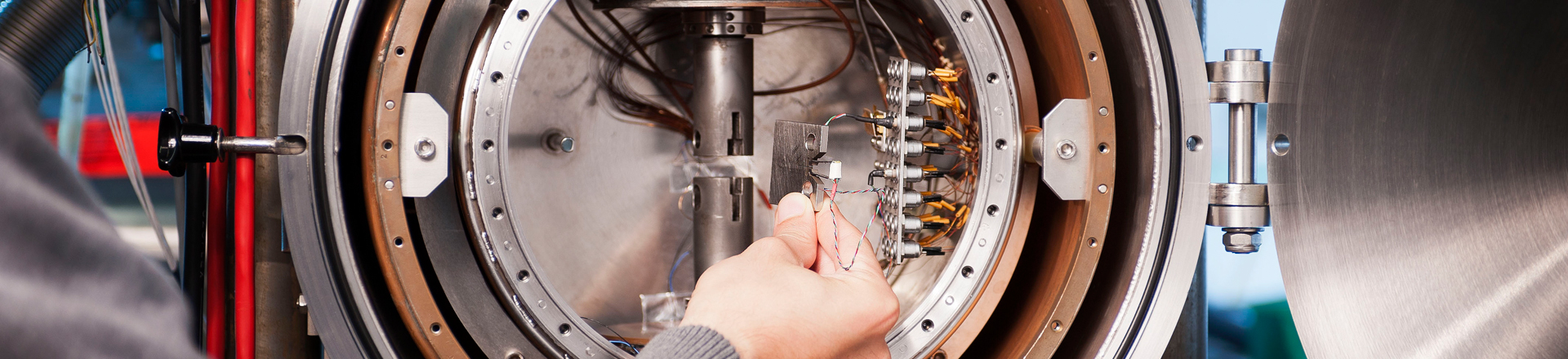

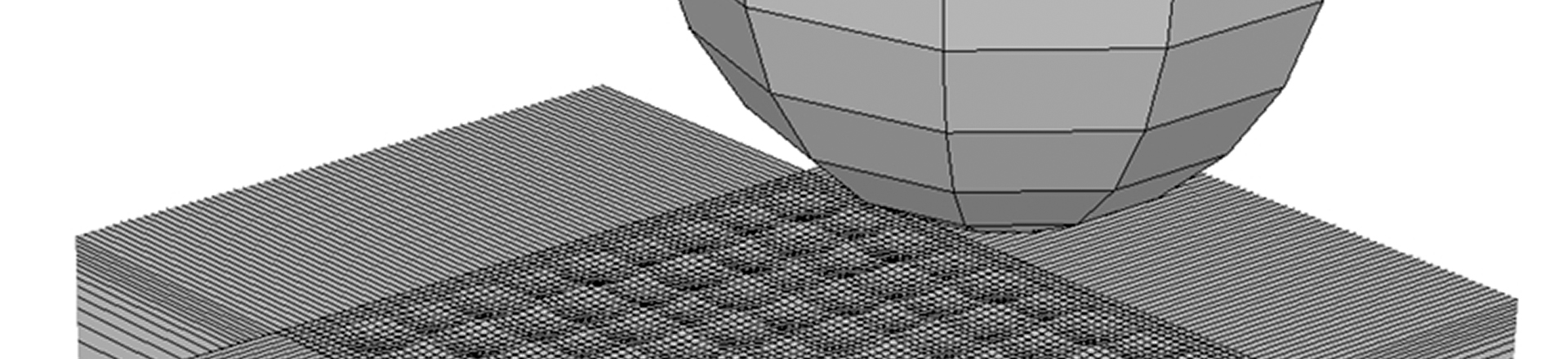

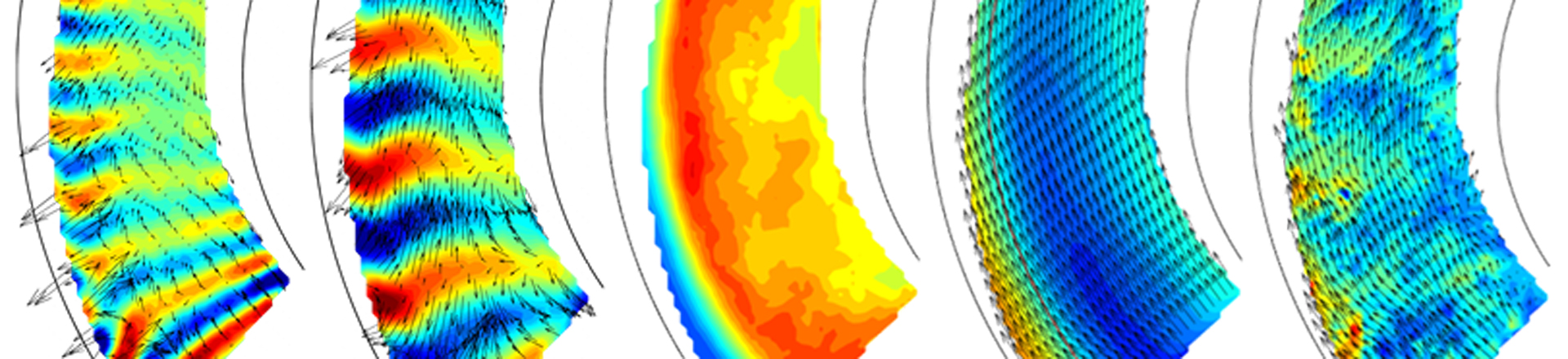

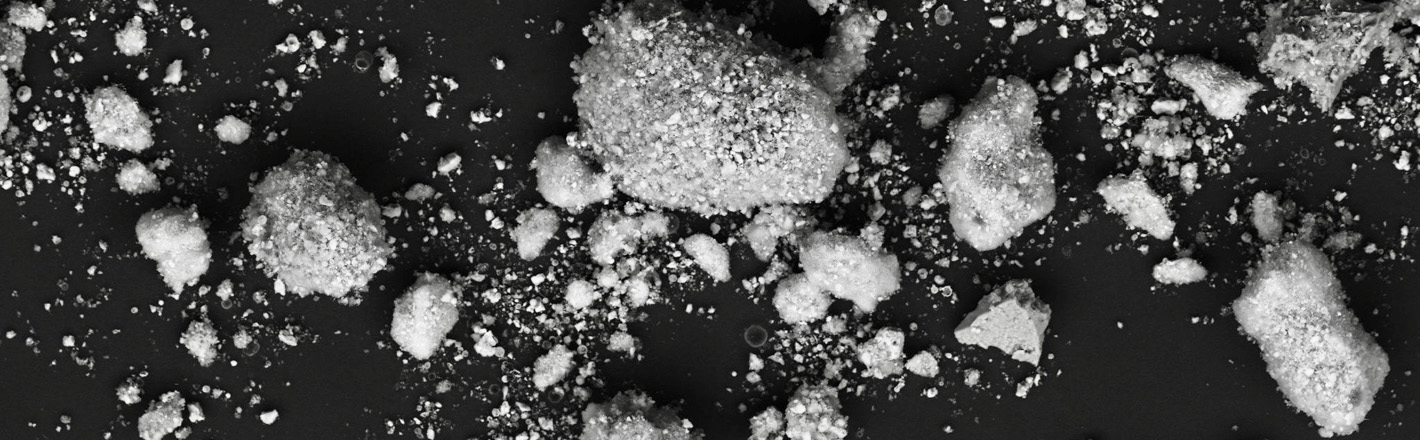

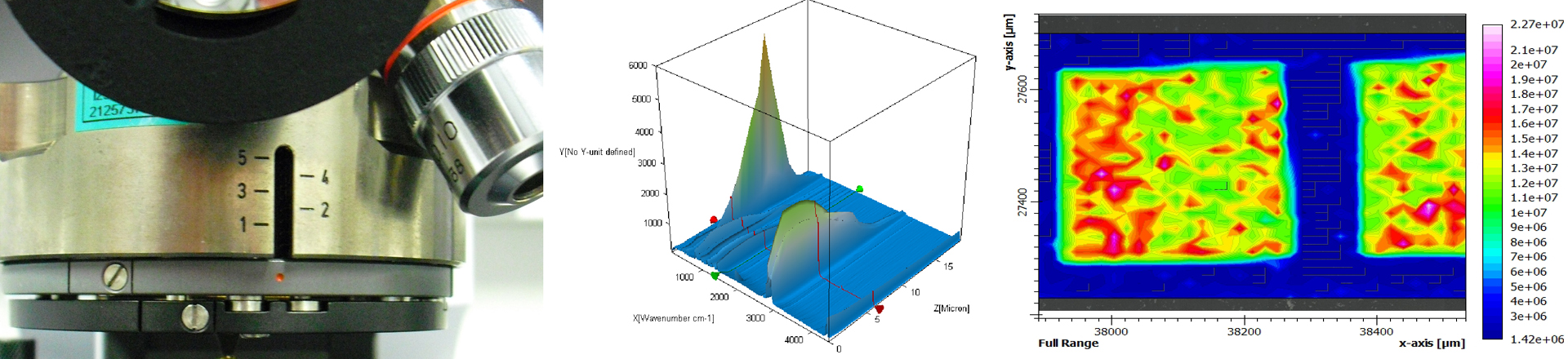

The applied methods include a multi-scale characterization of membrane retention, surface characterization and energy considerations in the application. In the methods, the range of small material samples (diameter 2.5 cm up to the industrial module) and pore sizes from dense reverse osmosis to functionalized microfiltration (0.2 nm to 0.45 μm) are investigated. A particular focus is on the retention and degradation of trace pollutants, which can be determined in the case of hormones, up to a detection limit of 0.1 ng / L. Furthermore, studies in real and environmentally relevant waters, speciation and interactions of solutes are core competencies of this TTE.

Our range of services includes:

initiation, management, planning, controlling of service projects with companies on topics of membrane materials & processes,

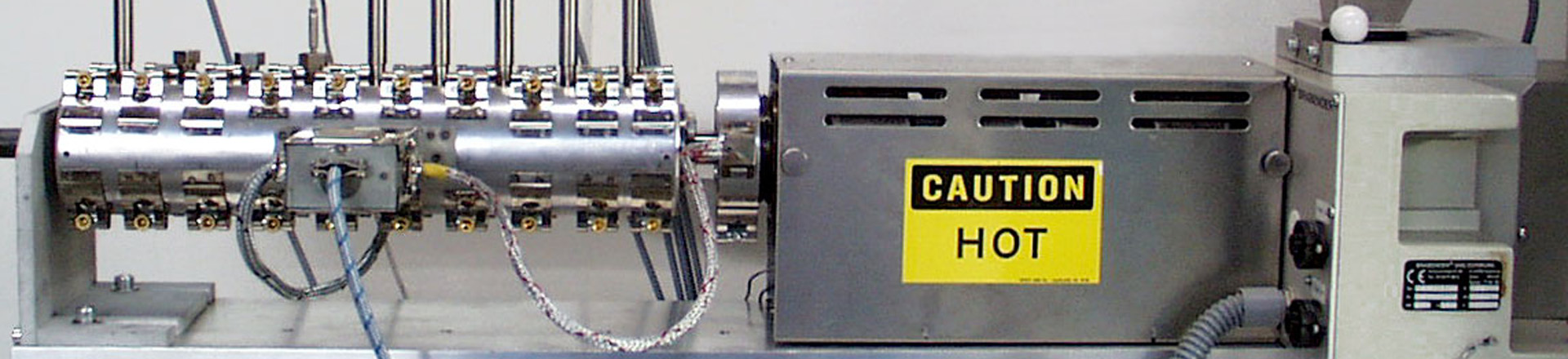

determination of permeability, salt retention, molecular cut-offs, trace contaminants retention, adsorption and degradation by methods that provide comparable results with spiral wound modules,

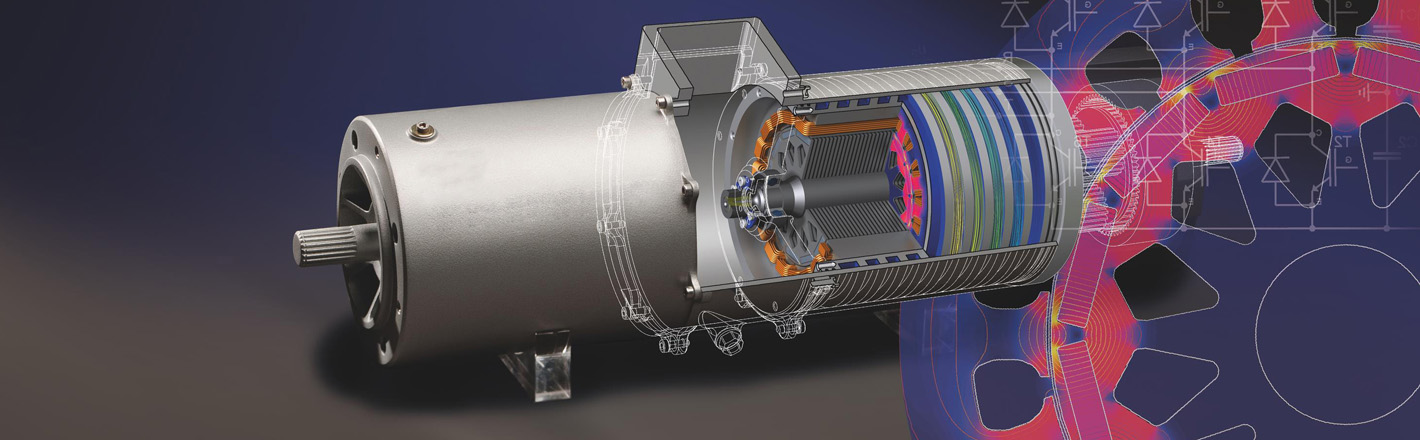

development of new membrane materials,

conception of new membrane processes, in particular renewable energy-operated, self-sufficient plants for developing countries and remote areas,

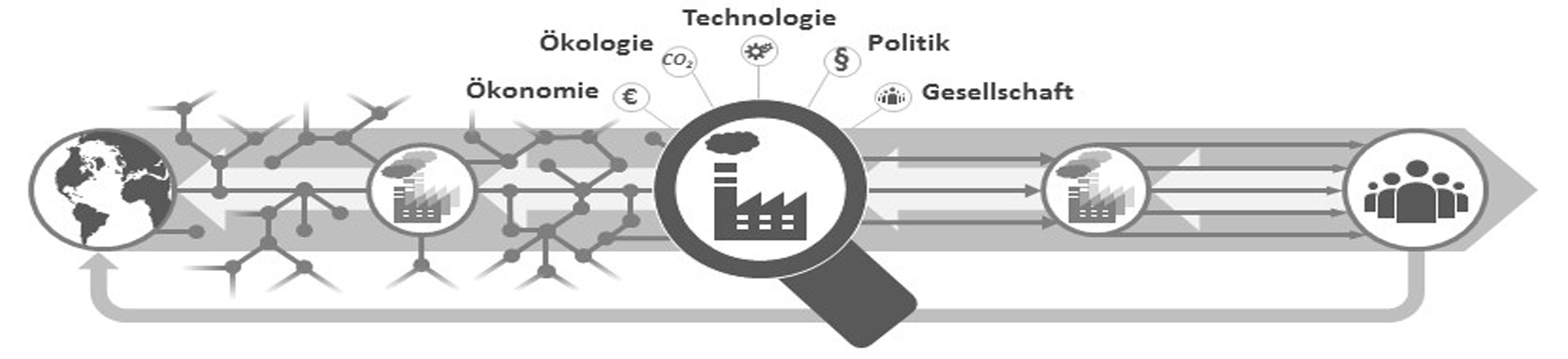

developed sustainable evaluation strategies and development of the application in water treatment together with the customer,

consultation on topics of membrane materials & processes as well as support of concrete innovation and start-up projects.

Prof. Dr.-Ing. Andrea Iris Schäfer is the founder and director of the Department of Membrane Technology at the Institute for Functional Interfaces (IFG-MT) at the Karlsruhe Institute of Technology (KIT).